5 Advantages of POLYSTAR for Your Plastic Recycling and Blown Film Businesses

As a leading manufacturer in the plastic industry, more than 4950 POLYSTAR plastic recycling machines and blown film extruders are operating in 110 countries today. This is a result of our satisfied customers, who have experienced the advantages of using POLYSTAR machines for their businesses. Here we have listed 5 of those advantages that are most pointed out based on our customers' feedback.

KUNG HSING: Innovative Multilayer Blown Film Designs — Key Considerations for Optimal Performance

In recent years, there have been remarkable advancements in blown film technology, leading to the creation of inventive multilayer blown film designs. These designs surpass traditional monolayer films in terms of barrier properties, strength, and versatility. Nevertheless, attaining peak performance necessitates thoughtful attention to various crucial factors throughout the design process. This article will delve into the essential considerations for achieving optimal performance in innovative multilayer blown film designs.

JANDI’S - The Differences in the Nature of PE & Biodegradable Material (PLA/PBAT Based)

According to the material supplier, bio-degradable material cannot be recycled easily. But, if not trying to recycle, the disposal of the waste & die-cut from bio-degradable material will become big additional expenses. Even if you may recycle the bio-degradable material, the time, space and workman ship required for the collection of the waste, will already create additional costs. Because of the above reasons, JANDI’S JIT is the best solution for the production of PLA/PBAT Bio-Degradable T-shirt bags.

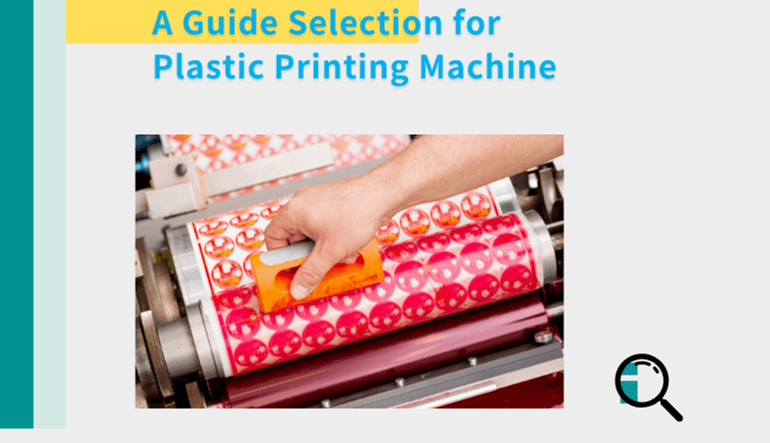

A Guide Selection for Plastic Printing Machine

Printing technology is crucial in the plastic and rubber industry for creating vibrant packaging. This article aims to introduce the most commonly used printing machines to global buyers, including rotogravure printing machines and flexographic printing machines. By providing descriptions, advantages, and features of these printing machines, you will understand how to select the printing equipment that suits your specific needs.

Blown Film Machine vs. Blow Molding Machine: Difference and Comparison

Blown film machines and blow molding machines are easily confused by many people, but they are two totally different machines and function differently as well. In this article, we will be discussing each machine and how they operate.

BARM for Success : How JANDI'S Implements Mr. Jerry's Concept to Enhance Machinery Supply

First of all, we would like to share some good news with you. While JANDI’S celebrate our 32nd anniversary on January 23, 2023, the General Manager of our company, Mr. Jerry M. J. Huang, graduated from the Department of Business Administration, National Chung Cheng University, and got his Ph.D. degree.

How to Start Plastic Recycling Business? A Complete Guide to Choosing the Right Recycling Machine

Plastic recycling is a growing industry. There are numerous factors to consider if you want to start a recycling business. You must decide what types of plastics you will recycle, determine the location of your business, research local and state requirements, research your customers, set up accounts with plastic buyers, and, most importantly, invest in a reliable plastic recycling machine.

Sustainability Benefits for Plastic Film Producers

Why do producers want to recycle plastics? Although plastic is a very popular material, on a global level, less than 10% of it is recycled. With plastic waste being in such a high supply, producers could benefit from incorporating recycling into their existing business model. A recent study by business and daily found that 72% of the respondents are actively buying more environmentally friendly products than they did 5 years ago.

KANG CHYAU: New Generation, New Prospect in Plastic Converting Industry

Kang Chyau has always been a leader in the field of Blown Film Machinery, not to mention how satisfying it is in terms of customization. The times are progressing and technology is innovating. This company with about 35 years of technology and experience has never neglected its pace. At the K-show exhibition this year, Kang Chyau is promoting the 3-layer blown film model: KMTL-55-65-55 E3.

Crucial Factors for a Complete Circular Economy

The production of plastic bags and plastic films around the globe is huge. In recent years, producers have implemented new technologies to complete a circular economy in their factories. To make this possible, producers need a plastic recycling system that produces good quality pellets and a blown film machine that can process up to 100% recycled plastic pellets.

The Proportion of Biodegradable Doesn‘t Have a Standard; It All Depends on How the Government Regulates It

During a pre-K press event, Messe Düsseldorf's Executive Director Petra Cullmann announced that the main themes for K 2022 (Oct. 19-26) will be digitization, climate protection, and the circular economy, which are also the direction governments and enterprises worldwide are currently working towards. Whilst climate issue is becoming a crucial topic worldwide and biodegradable materials are being valued more, Taiwan's film-blowing machine manufacturers have greatly improved their film-blowing technology. At K 2022, many film-blowing machine manufacturers in Taiwan mostly covered this topic in the exhibition.

Taiwan Machinery Industry Positioned to Lead the World Supply Chain

Since the 2019 K-Show until now, in just three years, the situation in the world has changed dramatically due to the outbreak pandemic. However, people are getting used to this unique circumstance. Including supply chains disconnected from the global economy. Even if the pandemic ends in the future, there will still be some uncertain factors such as geopolitics, trade war, and climate change. No one can guarantee the “broken chain” will not happen again. In the early stage of the pandemic, Taiwan successfully managed the situation and gained some buffer. This led Taiwan to become a trusted supply chain partner all over the world! The recycling industry is especially outstanding! From PIR to PCR, Taiwan's recycling technology is highly appreciated by global buyers.